Product Lineup

Super Low-Profile Type Pursuing Ease of Use

TWX220RⅢ25V was developed from the best-selling hybrid type vertical machine “TNXSeries,” which was widely used in many insert molding industries. This new hybrid type vertical injection molding machine is equipped with a new compound type clamping mechanism and offers super low-profile structures. It provides high safety and refined usability while reducing the costs for ancillary equipment and hydraulic oil.

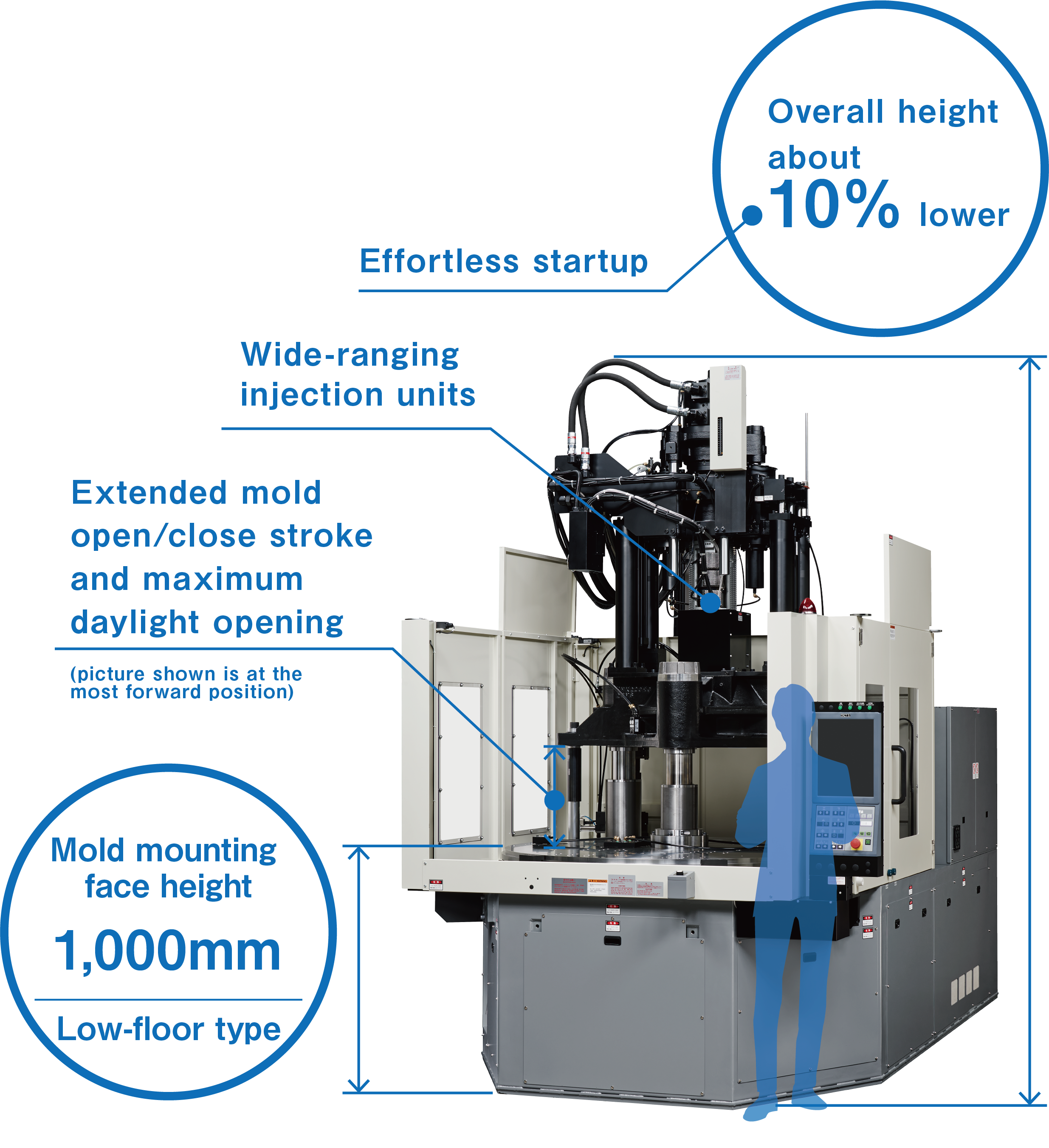

Super Low-Profile Type

In spite of being a 220t-class vertical injection molding machine, the height of the mold mounting face is 1,000mm, offering significantly lower height than its predecessors. It makes mold installation/setup, insert, and product takeout easier than ever before, significantly improving the usability and operability. Its optimized bed structure permits flexible robot layout. It also offers wider mold open/close stroke and maximum daylight opening, accommodating for the trends to use more complex and larger mold.

X-PUMP Hybrid type

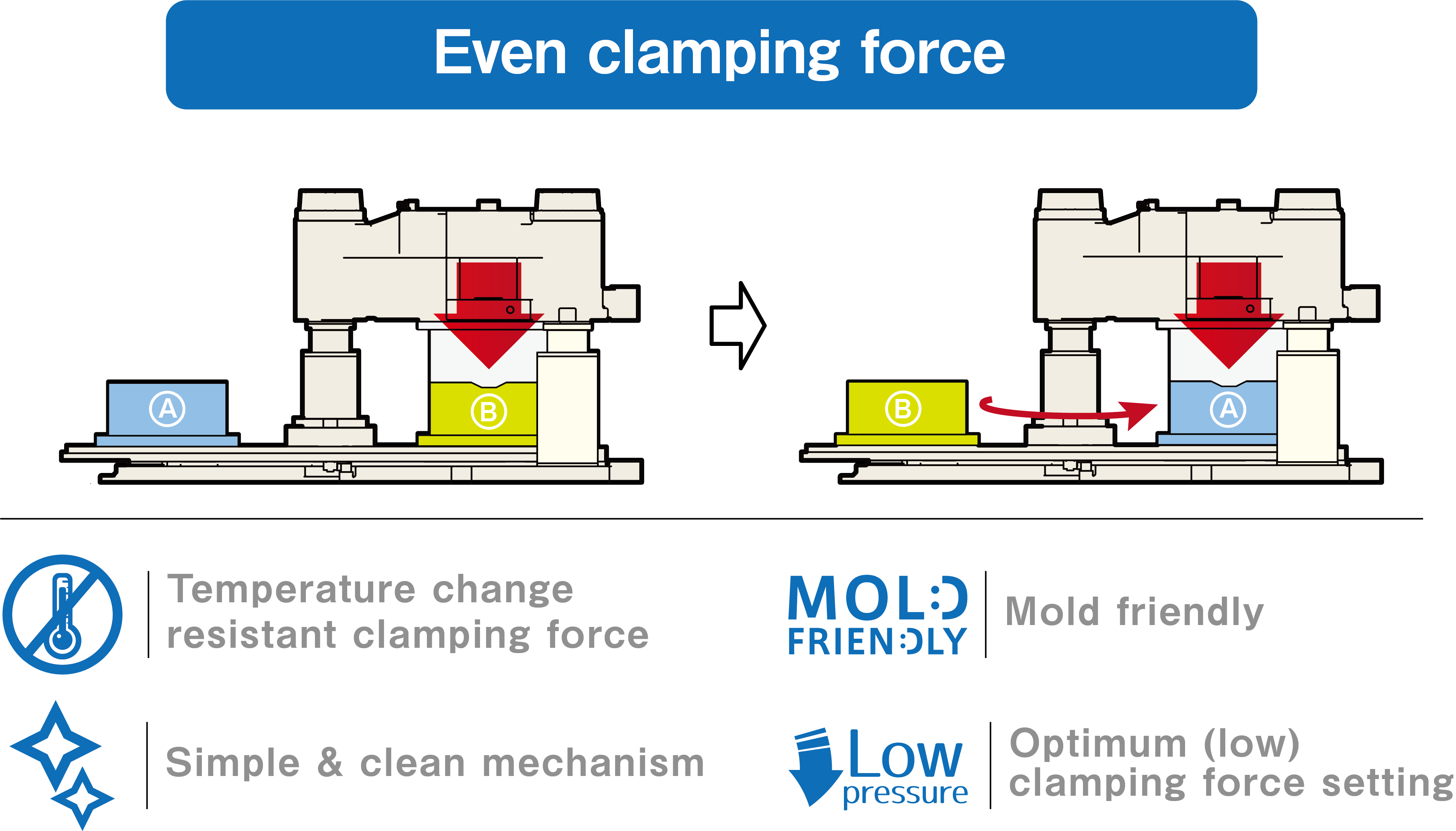

TWX220RⅢ25V is equipped with a direct-pressure type clamping mechanism that constantly transmits clamping force evenly to the mold according to the setting, even though it is a turntable type that mounts two molds on the lower die. Its performance is not affected by the temperature change in the mold or clamping unit. It’s easy to set optimal (low) clamping force to be gentle to the mold and machine; its simple and clean mechanism maintains the machine precision for a long time.

Suggesting Automated Insert Molding Systems

Nissei can suggest automated insert molding systems that maximize the advantages of the vertical rotary machines, which incorporate takeout robot, articulated robot, and two-arm robot ideal for different molded products and molding processes.

▲Inert molding automation demo using a two-arm robot.

Hybrid vertical injection molding machine TWX300RⅢ

Models TWX300RⅢ〔Turntable〕 Specification item 36V Screw diameter mm 45 50 56 Injection capacity ㎤ 201 254 314 Max. injection pressure MPa 223 181 144 Clamping force kN 2942 Clamping stroke mm 300~470 Mold thickness (min.) mm 450 Max. daylight opening mm 920 Die plate dimensions mm 1030 × 768 Ejector stroke mm 125